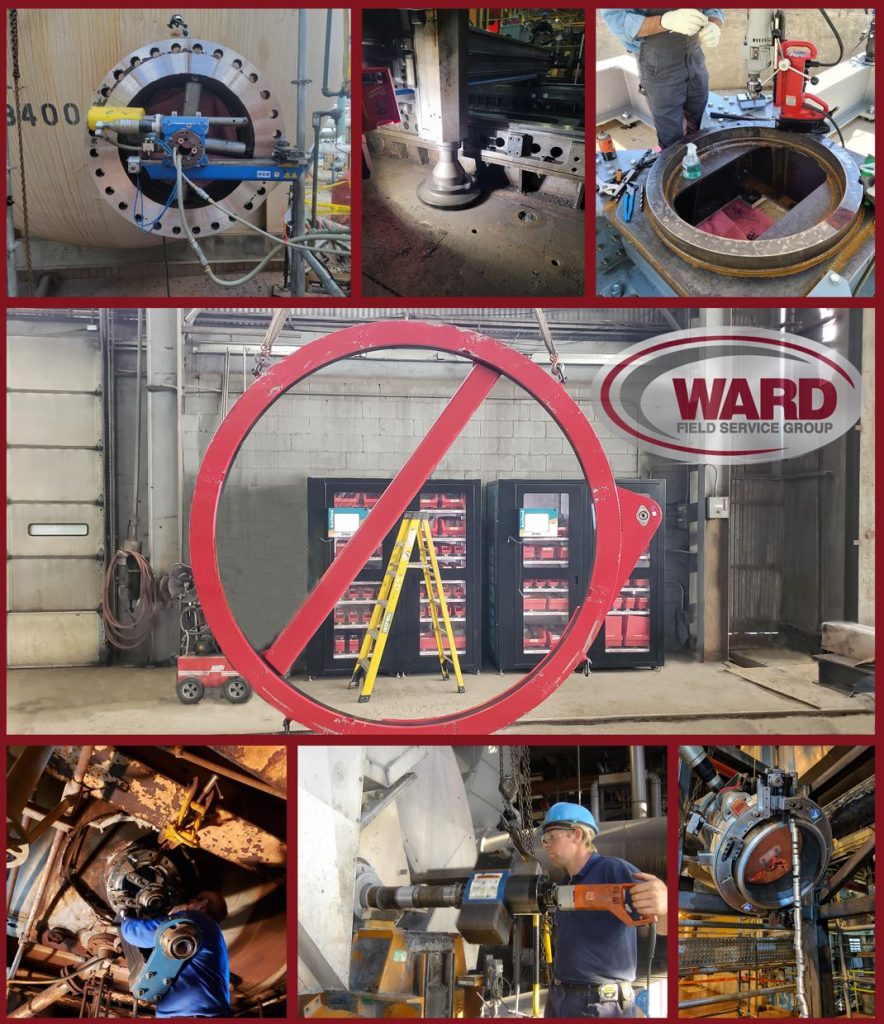

Did you know that Ward’s Field Service Group regularly performs all types of On-Site (In-Place/Field) Machining?

On-site machining is utilized when the equipment needing machining is too large or too unwieldy to remove and send to a machine shop. Instead of taking the component to the machine shop, you bring the machine shop to the component. Portable machining equipment is used to perform almost any machining operation that can be performed in a shop at the customer site in the field.

Common on-site machining operations include:

- Flange facing (restoring a damaged gasket/sealing surface)

- Pipe putting & beveling (providing a perfectly beveled pipe for welding, especially on thicker pipe schedules)

- Drilling (locating blind, through and threaded holes or removing broken or seized studs or bolts)

- Tapping (thread restoration, threaded insert installation)

- Milling (large surface preparation, pump/motor base leveling, or elevation changes)

- Boring (bearing/sleeve removal, fit alignments, counterbores)

- Turning (shaft bearing and sealing area resurfacing)

Often, extremely tight tolerances are specified. In those cases, a laser tracker or other coordinate measuring machine (CMM) can be utilized to take as-found data, provide precise dial-in, and confirm as-left data.

Ward can turnkey any on-site machining project of any size in any location and – if there is welding required on ASME Code equipment, we can utilize our NBIC R-Stamp and handle all the necessary Code repair documentation paperwork.