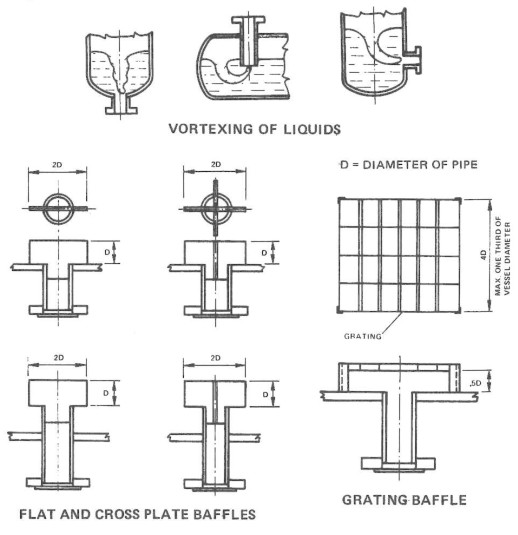

Vortex breakers are simple devices used to prevent the formation of vortices, or swirling patterns, at the drain nozzle in a tank or pressure vessel. If a vortex forms when draining a vessel, the flow will be reduced, and air could be introduced into the drain pipe. This could cause cavitation in downstream pumps or other process issues. Vortex breakers promote smoother and more efficient fluid flow, reducing turbulence and buildup of solids. They can be designed in various ways, but the simplest and most common design uses two plates welded in the shape of a cross and placed over the vessel drain nozzle.