The primary code that applies to nearly all pressure vessels and heat exchangers is the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1. It contains all the requirements for design, materials, fabrication, testing, and certification of new vessels. Since Section VIII is a construction code, the scope of the code ends once the vessel is certified. It does not cover any aspects of the vessel’s service life, such as installation, operation, inspections, or maintenance. For those topics, ASME publishes a series of PCC (Post-Construction Committee) Standards.

The primary code that applies to nearly all pressure vessels and heat exchangers is the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1. It contains all the requirements for design, materials, fabrication, testing, and certification of new vessels. Since Section VIII is a construction code, the scope of the code ends once the vessel is certified. It does not cover any aspects of the vessel’s service life, such as installation, operation, inspections, or maintenance. For those topics, ASME publishes a series of PCC (Post-Construction Committee) Standards.

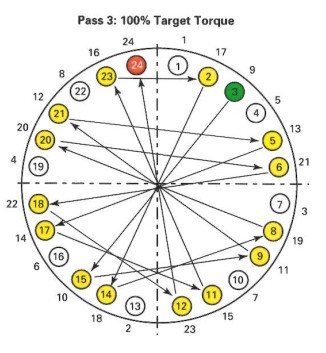

For example, bolted joints in pressure equipment are usually not given the same attention as welded joints but can be a major source of leaks in plants. ASME’s PCC-1 Standard, Pressure Boundary Bolted Flange Joint Assembly, offers detailed guidance on how to achieve reliable, leak-free joints in service. It covers gasket selection, bolt lubrication, recommended tightening patterns, tool calibration, and controlled bolt loading methods such as torque and tensioning. Appendix O gives detailed methods for determining the required bolt stress for a joint, and the required torque to achieve it.

We will cover other ASME PCC standards in next month’s update.