Ward: The Field Machining Partner You’ve Been Looking For—But Didn’t Expect

When most people think of Ward Vessel & Exchanger, their mind immediately goes to the Design/Fabrication/Repair of ASME Pressure Vessels, API Tanks, and Heat Exchangers—and they’re right. But here’s what many don’t realize: Ward is also a premier Field Machining provider, and that matters more than you might think.

Why Field Machining with Ward Is Different

Field machining isn’t just about bringing a machine to a job site. It’s about precision, planning, and protecting the integrity of your equipment. Any machining company can resurface a flange or remove a stud. But can they ensure the work doesn’t compromise your pressure boundary? Can they calculate the impact of material removal on ASME Code compliance? Can they deliver an unparalleled experience from the first call through demobilization and even invoicing?

At Ward, we can—and we do. With a building full of engineers who live and breathe ASME and API codes, we don’t just fix the obvious problem. We anticipate the details, plan for contingencies, and keep your project moving forward—even when the unexpected happens.

What We Bring to the Table

- Engineering Expertise: Our team performs calculations to ensure equipment ratings and Code Stamps remain intact.

- NBIC R-Stamp Capability: If weld overlay or build-up is needed, we handle it in-house—no delays, no outsourcing.

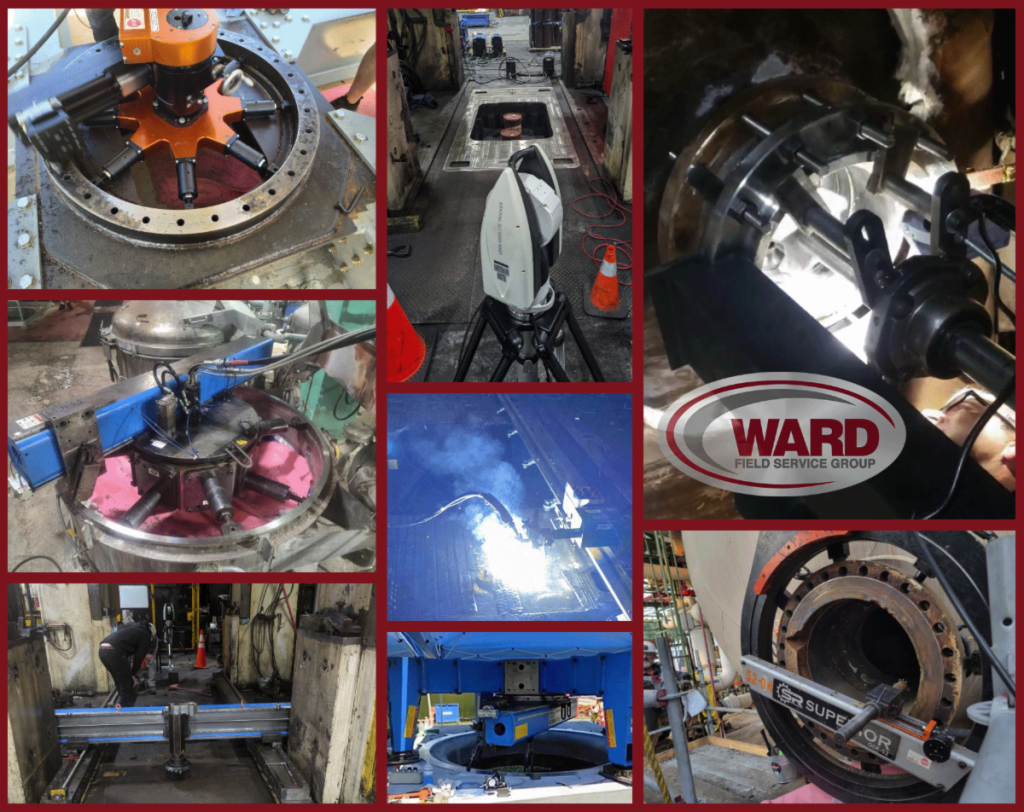

- Precision Metrology: Laser trackers and scanning ensure alignment and dimensional accuracy from start to finish.

- Comprehensive Services: From flange facing and line boring to milling, drilling, pipe cutting/beveling, and even hydro turbine/dam/nuclear work—we’ve got you covered.

Industries We Serve

Most of our customers are in the petrochemical industry, but our expertise goes far beyond. We understand the power generation (including nuclear) sector, petroleum refining, and general heavy industry. With decades of experience inside these environments, we know the standards, the challenges, and the stakes. Whether you need help on a single one-day project or a multi-week Turnaround & Outage Support Team, it’s business as usual for Ward.

Why It Matters

Choosing a generic machining vendor might seem easier, but it often leads to risk, delays, and costly rework. Ward’s Beyond the Blueprint™ approach means we look beyond the immediate task to the bigger picture—your safety, compliance, and uptime.

And because we know your downtime is already inconvenient, our Field Service team operates with one additional goal: “Inconvenience the customer as little as possible.”

We take ownership of the entire process—from planning to execution—so you can focus on running your plant while we handle the details. That’s just part of the Ward Way™.

How We Deliver More

- Engagement: Responsiveness isn’t a promise—it’s a practice. We respond the same day because communication is the foundation of trust.

- Excellence: Our Center of Engineering and Manufacturing Excellence powers every decision we make, ensuring precision and efficiency from RFQ to completion.

- Experience: We’re the safe choice. With decades of proven performance, we deliver quality, on-time results, and peace of mind—every time.

The Bottom Line

Whether your project is in petrochemical, power generation, refining, nuclear, or any other heavy industry, the principle is the same: you need a partner who understands the codes, the risks, and the stakes. If your work involves pressure vessels, reactors, heat exchangers, tanks—or almost any critical component that demands precision machining and engineering expertise—Ward is ready.