New Series Introduction: Know Your Metal!

At Ward, we work with a wide range of materials—from shiny stainless to stubborn duplex to the occasional high-nickel diva. And while our welders, fitters, and engineers might all have their favorites (and strong opinions about the rest), one thing is certain: each alloy has its own personality, rules, and “gotchas”.

This six-part series, Know Your Metal, takes a practical, plainspoken look at the materials that show up most in our world of field service and shop fabrication work. We’ll focus on how they behave, how they misbehave, and what we’ve learned from working with them in real-world conditions.

Here’s what’s ahead:

- Carbon Steel – The Workhorse

- Stainless Steel – Shiny, but Sensitive

- High-Nickel Alloys – The Divas of Durability

- Duplex Stainless – Strong but Stubborn

- Titanium – The Future We’re Getting Ready For

- Field Comparisons, Failures, and Fixes

Whether you’re in operations, engineering, or just here for the war stories, we hope this series gives you a clearer understanding of what these metals are really like once the cutting starts and the arc gets lit.

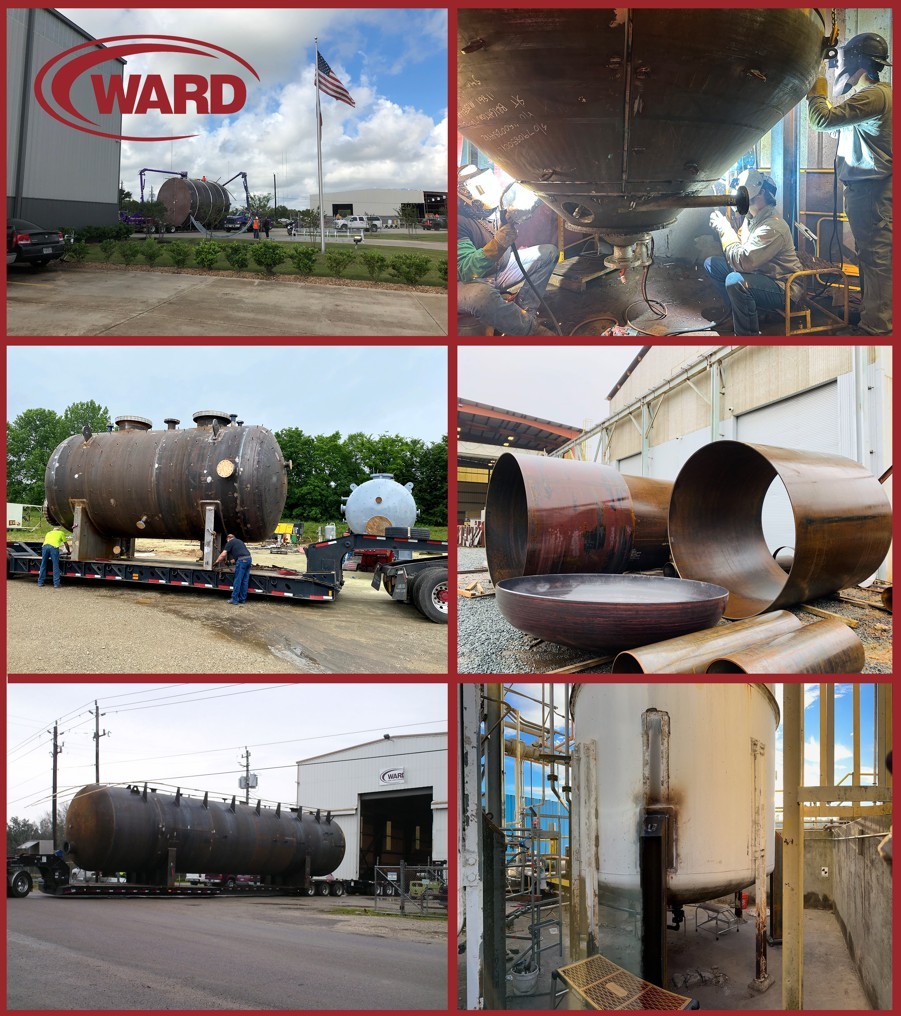

Know Your Metal (Pt. 1): Carbon Steel – The Workhorse

If metals were employees, carbon steel would be the one who shows up early, doesn’t ask for much, and only occasionally sets something on fire. It may not be the flashiest material on the project list, but it’s everywhere—structural skids, process ductwork, tank internals, and the occasional stubborn vessel.

Here at Ward, carbon steel isn’t our bread and butter—that honor goes to stainless, duplex, and high-nickel alloys—but we still find ourselves pulling it into scope when it makes the most sense: for cost, constructability, or because the client spec says so and we’re not here to argue (much).

The Good: Why It’s Still a Favorite

- Versatile and available: From A36 plate to SA-516 Grade 70 vessel material, carbon steel is everywhere and easy to source.

- Forgiving to weld: It tolerates a wide range of procedures, preps, and operator finesse.

- Cost-effective: When budgets are tight, carbon steel keeps projects moving—assuming the corrosion allowance cooperates.

The Bad: Where It Gets You

- Corrosion lurks: Uncoated, unmaintained, or poorly cleaned surfaces become future repair jobs waiting to happen.

- Weld repairs escalate fast: A “grind and go again” mindset can backfire in thicker sections or poorly preheated areas—hello, hydrogen-induced cracking.

- Hydrogen embrittlement: Hydrogen embrittlement weakens carbon steel by introducing microscopic flaws and lessening ductility, reducing its ability to absorb stress without fracturing, potentially leading to catastrophic failures.

Tips from the Trenches

- Preheat when required: Especially on thick materials, or when ambient temps are low. It’s cheap insurance against cracking. Remember, there are ASME Code requirements that prescribe a mandatory post-weld heat treat with materials over 1.5″ thick.

- Prep like it matters: Mill scale, oil, or rust in or near the joint? Grind it. Wire brush it. Repeat. If it looks like a 1980s pickup truck fender, it’s not ready to weld.

Next Month

We leave the rough-and-ready behind and move into shinier territory with Part 2: Stainless Steel – Shiny, but Sensitive. We’ll talk sugaring, distortion, and why your rag selection can make or break a finish.