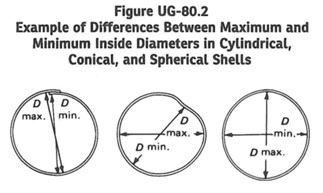

The ASME code gives tolerances for shell roundness in section UG-80, but this section is often misunderstood. UG-80 has two parts, (a) and (b). UG-80(a) applies to all vessels. It states that when measuring diameters of the vessel, the difference between the minimum and maximum measurements at any cross section cannot exceed 1% of the diameter. There is an extra allowance when measuring near nozzle openings.

The ASME code gives tolerances for shell roundness in section UG-80, but this section is often misunderstood. UG-80 has two parts, (a) and (b). UG-80(a) applies to all vessels. It states that when measuring diameters of the vessel, the difference between the minimum and maximum measurements at any cross section cannot exceed 1% of the diameter. There is an extra allowance when measuring near nozzle openings.

UG-80(b) only applies to vessels with some amount of external pressure design and rating. For this check, a template is made at the nominal diameter of the vessel. Then measurements are made between the vessel shell and the template. A calculation is made to determine the allowable deviation from the template, and the required length of the template.

So UG-80(a) is a tolerance for overall vessel roundness and ovality, but UG-80(b) is a check for local distortions in a round shell, which can increase the chances of buckling under external pressure.