Did you know that Ward’s World-Class Engineering Group regularly works in-step with our Field Service Division to help our customers with re-rates on tanks, vessels, and heat exchangers?

Often, our customers find themselves with an asset that is in suitable condition, although its original pressure/vacuum/temperature rating may not fit the bill for its intended use.

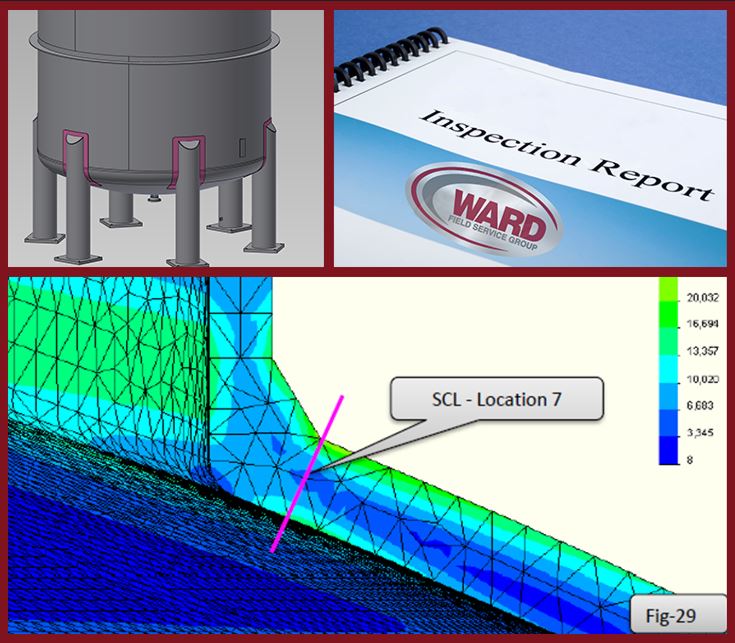

In those cases, code studies need to be undertaken to determine if the unit can withstand a higher pressure, a full vacuum rating or a temperature rating increase. Those studies generally lead to modifications to the equipment such as stiffener rings, etc.

Ward can perform the Engineering work, then Field Services can handle any alterations necessary to get the equipment to satisfy the new rating.

As a general rule, an official “recent” inspection report is required so Engineering has assurances that the equipment is in suitable condition with wall thicknesses, etc. Ward can also provide an Internal or External Inspection based on API 510, as we have certified API 510 inspectors on full-time staff.

Lastly, Ward steps outside of the norm on a regular basis when it comes to providing Engineering Services that are more than just a re-rate. For instance, we recently performed an engineering study to prove out a repair plan to remove & replace the corroded skirt on a large tower at a gulf coast petrochemical plant.

Trust Ward’s Engineering expertise to handle all the small (but not unimportant) Engineering studies on your pressure equipment that the pure Engineering companies are hesitant to take on due to their small size. Then, watch as we turn around that work quickly, then engage our Field Service Group to perform any modifications on very quick timelines, keeping your plant up and running profitably.