Over the next few newsletters, we will discuss various jacket types available for pressure vessels. Jackets are commonly used for heating or cooling the contents of a vessel, or to maintain a certain temperature for a reaction to take place. By circulating a heating or cooling medium (such as steam, cooling water, or a heat transfer liquid) through the jacket, the temperature of the contents of the vessel can be regulated.

Over the next few newsletters, we will discuss various jacket types available for pressure vessels. Jackets are commonly used for heating or cooling the contents of a vessel, or to maintain a certain temperature for a reaction to take place. By circulating a heating or cooling medium (such as steam, cooling water, or a heat transfer liquid) through the jacket, the temperature of the contents of the vessel can be regulated.

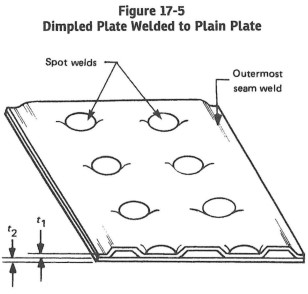

One commonly used configuration is a dimpled jacket. This type uses a section of sheet metal that is formed with equally spaced depressions, or dimples. The dimples provide contact points to weld the jacket to the vessel shell or head. After welding, a space is created for heat transfer medium to flow on the outside of the shell or head. The ASME code pressure rating of the assembly is based on proof testing of a sample panel of the jacket.

This type of jacket is usually less costly than other types. They also take up very little space, if that is a concern. However, inconsistent flow patterns in the jacket can result in uneven heating or cooling. Also, dimpled jackets cannot support pressure and temperature ratings as high as other jacket types. Please let us know if you have any questions about heating or cooling jackets.

Please contact us with any questions about the ASME Code.