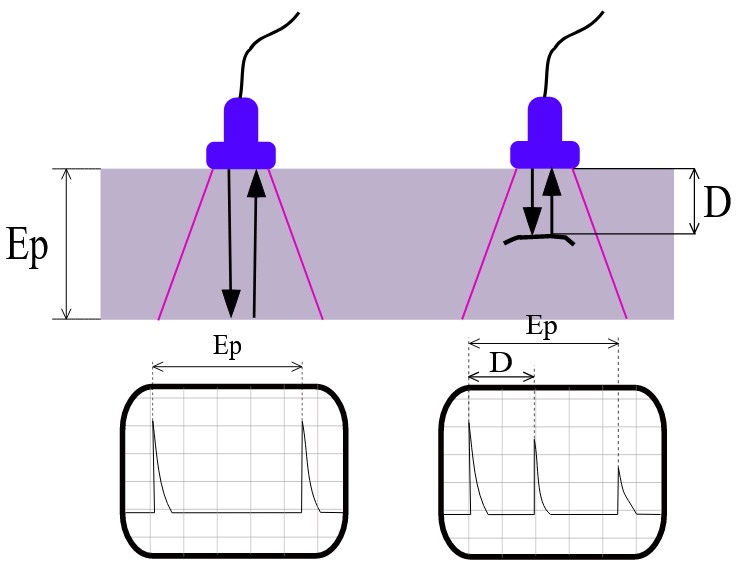

Ultrasonic Testing (UT) is a volumetric testing method that can detect flaws inside a material without them being open to the surface. Several different forms of UT are commonly used, including straight beam, shear wave, and phased array. All forms of ultrasonic testing work in the same way as radar or sonar, in which a signal pulse is sent out from a transducer, and the equipment listens for the reflection of the signal to return. In this case, the pulse is a sound at a frequency outside of what humans can hear. How long it takes for the signal to return, or even if it does return, will determine the results of the test. Straight beam ultrasonic testing is used to measure the thickness or find flaws in smooth, flat items such as plates. Access is only needed to one surface of the plate, which makes this test a great option to check for corrosion of pressure vessels, without needing to enter the vessel. The ultrasonic beam travels to the other side of the material and bounces back. The longer the signal takes to return, the thicker the plate is. If the signal returns earlier than expected, the plate may be thinning due to corrosion, or have a flaw such as a delamination. Part 2 of this article will discuss other forms of UT testing.