How does the ASME Code determine how thick nozzles should be? While the standard code calculation for a cylinder under internal pressure often gives minimal requirements—frequently less than 1/16″ for typical nozzles—this alone doesn’t provide adequate structural integrity. The small required thickness is due to the radius term in the formula, as most nozzle cylinders have relatively small diameters.

How does the ASME Code determine how thick nozzles should be? While the standard code calculation for a cylinder under internal pressure often gives minimal requirements—frequently less than 1/16″ for typical nozzles—this alone doesn’t provide adequate structural integrity. The small required thickness is due to the radius term in the formula, as most nozzle cylinders have relatively small diameters.

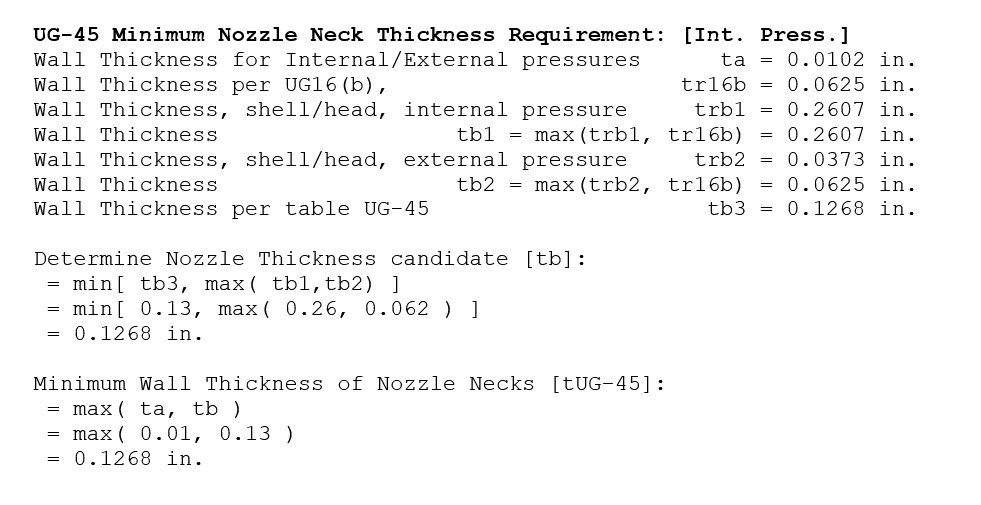

The Code recognizes that nozzles face various challenges beyond internal pressure. They must withstand external loads from connected piping and equipment, as well as mechanical stresses from routine maintenance activities like bolt torquing. To address these practical concerns, Section UG-45 establishes minimum thickness requirements through a comparison of multiple factors: the pressure-based thickness calculation, standard pipe wall thickness, and the required thickness (tr) for the shell or head.

For smaller nozzles, this often results in thickness requirements equivalent to standard wall or Schedule 40S pipe specifications. This more robust approach ensures nozzles maintain their structural integrity under real-world operating conditions, rather than relying on pressure calculations alone.