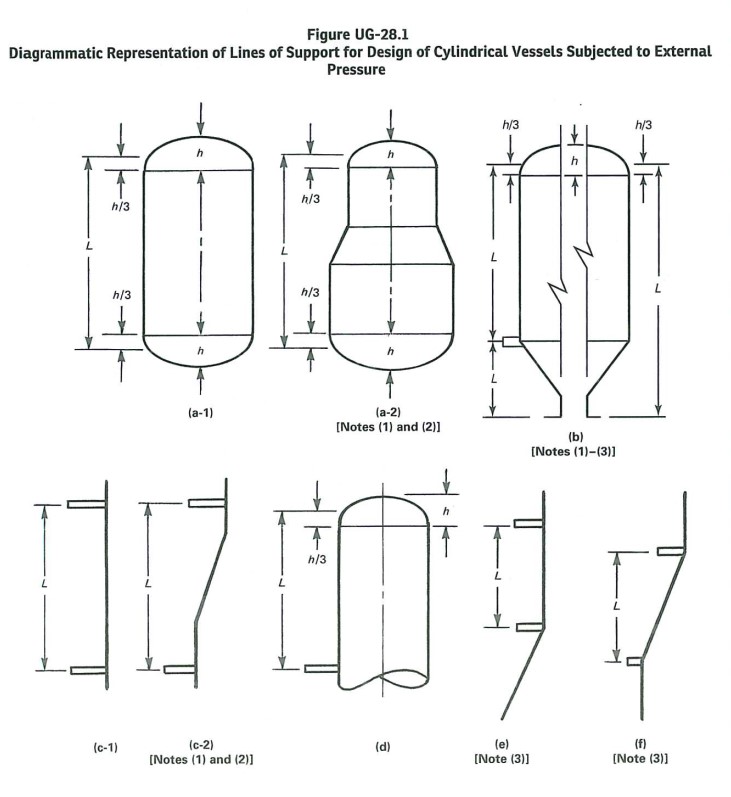

When designing a cylindrical shell for internal pressure, the basic variables needed are the diameter, pressure, material allowable stress, and weld efficiency. The length of the shell is not a consideration. So if everything else is the same, the required thickness of a cylinder due to internal pressure will be the same if it is 5 feet long or 500 feet long. Now let’s consider external pressure on a shell. Designing a vessel for an internal vacuum means it needs to resist external atmospheric pressure. If a cylinder fails due to external pressure, it buckles (as opposed to breaking apart under internal pressure). The buckling length of a shell is important to determine how much external pressure it can hold. Longer shell lengths are easier to buckle. Designers use stiffening rings on longer shells to reduce the buckling length and strengthen a shell for external pressure. Contact us if you have any questions about internal or external pressure design.

When designing a cylindrical shell for internal pressure, the basic variables needed are the diameter, pressure, material allowable stress, and weld efficiency. The length of the shell is not a consideration. So if everything else is the same, the required thickness of a cylinder due to internal pressure will be the same if it is 5 feet long or 500 feet long. Now let’s consider external pressure on a shell. Designing a vessel for an internal vacuum means it needs to resist external atmospheric pressure. If a cylinder fails due to external pressure, it buckles (as opposed to breaking apart under internal pressure). The buckling length of a shell is important to determine how much external pressure it can hold. Longer shell lengths are easier to buckle. Designers use stiffening rings on longer shells to reduce the buckling length and strengthen a shell for external pressure. Contact us if you have any questions about internal or external pressure design.