Positive material identification (PMI) ensures that the components and welds in a unit are actually the correct materials. Following proper procedures for material ordering, receiving, and traceability should prevent any…

Visual Inspection (VT) is the oldest and most basic method of inspection. It is the process of looking over a piece of equipment using the naked eye to look for flaws. It…

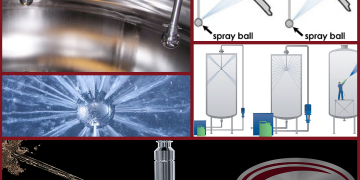

Have you ever given thought to the internal cleanliness of pressure equipment? The use of tanks and vessels can vary widely. In some facilities, a given vessel operates with a…

Like magnetic particle testing, this is a surface-only inspection method that can find imperfections such as cracks, surface porosity, seams, laps, etc. Unlike MT, it can be used on magnetic…

Mechanical Integrity (MI) can be defined as the management of critical process equipment to ensure it is designed and installed correctly and that it is operated and maintained properly. MI…

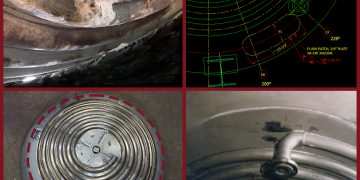

Back in November and December, in our “Some Equipment Cannot Be Saved” thread, we discussed ongoing work on a stainless steel pressure vessel that suffered from significant Stress Corrosion Cracking…