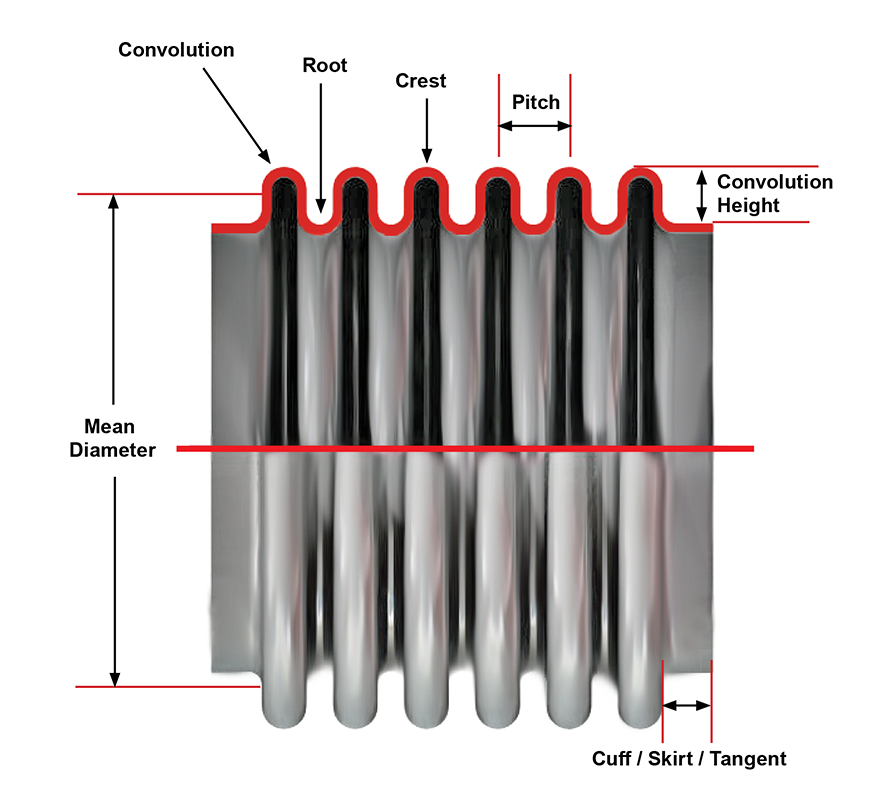

The last newsletter discussed how differential thermal expansion in fixed tubesheet exchangers might require an expansion joint. Two types of expansion joints are commonly used in exchangers: flanged and flued (thick-wall), and bellows (thin-wall). The flanged and flued type allows less expansion but offers more durability and is very unlikely to ever leak. If the required amount of expansion between the tubes and shell is too high for a flanged and flued joint, a bellows-type joint must be used. These joints feature thinner walls and multiple convolutions, making them more flexible but also more vulnerable to mechanical damage. Even minor damage can cause a leak that is very difficult to repair. For this reason, bellows-type joints are normally supplied with a protective shroud. Proper expansion joint selection is critical to ensuring the long-term reliability and performance of a heat exchanger.