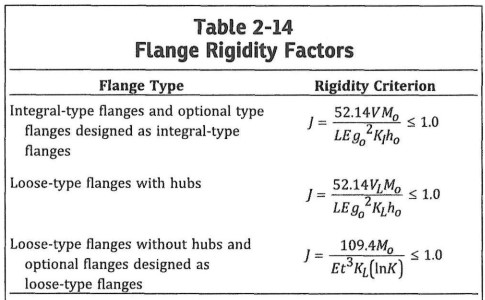

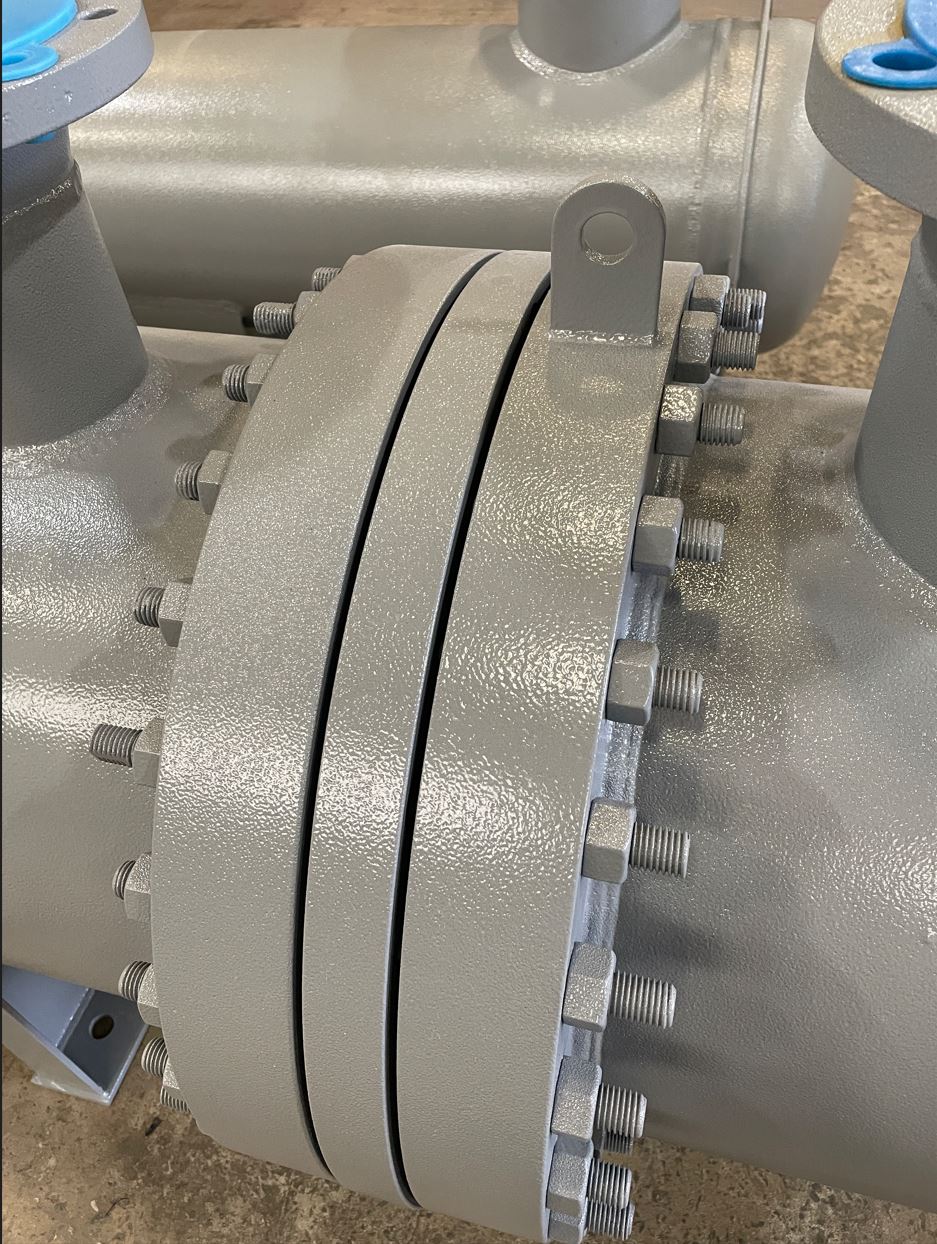

In the ASME code, Appendix 2 gives the rules and formulas for design of custom flanges (in other words, flanges that are not standard Class 150, 300, etc). Although the Appendix 2 design method has been in place since the 1950’s, it was found that in practice certain flange designs were rotating enough to leak, without being overstressed in calculations. Flange rotation occurs when the outside edges of the flanges bend towards each other, using the gasket as a pivot point. To correct this problem, ASME added the mandatory rigidity check in the 2007 edition of the code. All new flange designs must meet this criterion, which often requires a thicker flange. However, the code does allow for this check to be omitted in certain cases, based on “successful service experience” with the same design, and as long the equipment is in non-lethal and non-flammable service, and below the design limits of 366°F and 150 psi. See paragraph 2-14 for details, or feel free to ask us if you have any questions.

In the ASME code, Appendix 2 gives the rules and formulas for design of custom flanges (in other words, flanges that are not standard Class 150, 300, etc). Although the Appendix 2 design method has been in place since the 1950’s, it was found that in practice certain flange designs were rotating enough to leak, without being overstressed in calculations. Flange rotation occurs when the outside edges of the flanges bend towards each other, using the gasket as a pivot point. To correct this problem, ASME added the mandatory rigidity check in the 2007 edition of the code. All new flange designs must meet this criterion, which often requires a thicker flange. However, the code does allow for this check to be omitted in certain cases, based on “successful service experience” with the same design, and as long the equipment is in non-lethal and non-flammable service, and below the design limits of 366°F and 150 psi. See paragraph 2-14 for details, or feel free to ask us if you have any questions.