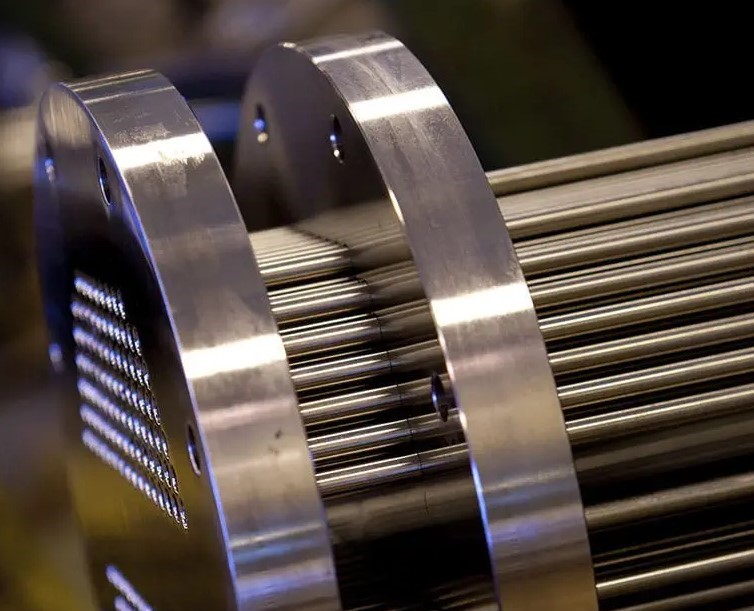

If your process absolutely cannot tolerate mixing of the shell side and tube side fluids in a heat exchanger due to safety or process purity concerns, you may want to consider a double tubesheet design. In these designs, a secondary tubesheet is added at each end to provide an additional seal and further separate the shell and tube sides of the exchanger. Double tubesheets prevent cross-contamination of fluids in the event of leaks at the tube to tubesheet joint. The tubes are sealed at both tubesheets by expansion or welding.

If your process absolutely cannot tolerate mixing of the shell side and tube side fluids in a heat exchanger due to safety or process purity concerns, you may want to consider a double tubesheet design. In these designs, a secondary tubesheet is added at each end to provide an additional seal and further separate the shell and tube sides of the exchanger. Double tubesheets prevent cross-contamination of fluids in the event of leaks at the tube to tubesheet joint. The tubes are sealed at both tubesheets by expansion or welding.

The annular space between the tubesheets may be vented or drained to detect any leakage and avoid pressure buildup, or it may be left open. Design guidelines for double tubesheets can be found in the TEMA standard. Although they may add considerable cost to the exchanger, double tubesheet heat exchangers should be considered for applications where the fluids have high purity requirements or corrosive properties.