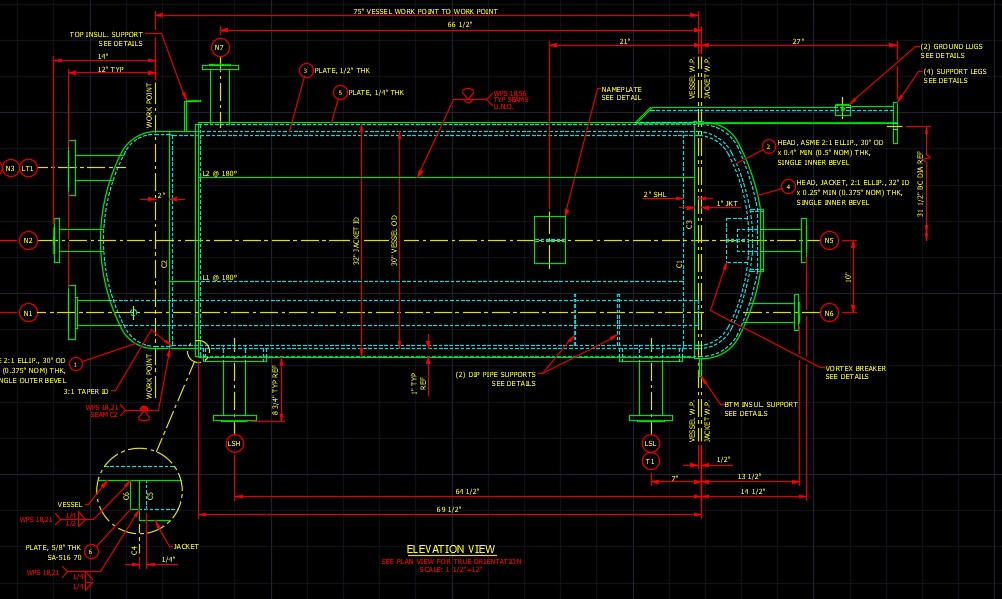

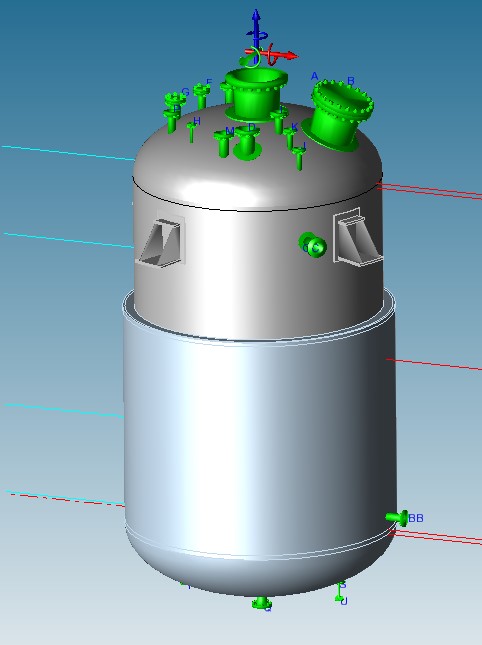

In the last newsletter, we discussed dimpled type jackets for pressure vessels. For some applications, a conventional type jacket might be the best choice. A conventional jacket consists of a secondary shell or head outside of the main vessel. The annular space between the two pressure chambers is where heating or cooling medium is circulated, to transfer heat to or from the contents of the vessel. Baffles are usually arranged in the jacket space to direct flow.

In the last newsletter, we discussed dimpled type jackets for pressure vessels. For some applications, a conventional type jacket might be the best choice. A conventional jacket consists of a secondary shell or head outside of the main vessel. The annular space between the two pressure chambers is where heating or cooling medium is circulated, to transfer heat to or from the contents of the vessel. Baffles are usually arranged in the jacket space to direct flow.

Advantages of this jacket type are that higher pressures and temperatures can be used compared to a dimpled jacket, and the full surface area of the inner vessel can be used for heat transfer. Higher flow rates of heat transfer medium can also be used, and less pressure drop is required.

A disadvantage is that as jacket pressure increases, the inner vessel needs to be thicker to resist the external pressure. A thicker vessel not only adds cost, but it also reduces heat transfer. Conventional jackets become very expensive on larger vessels, but they are often the best choice for smaller vessels. Contact us if you have any questions about heating or cooling jackets.

Please contact us with any questions about the ASME Code.