#5: Materials…

Materials are an important aspect of repair work that must be considered in each and every circumstance. Experienced Field Service and Repair companies who know their business often post disclaimers about not being responsible for weldability or machineability of the original base materials.

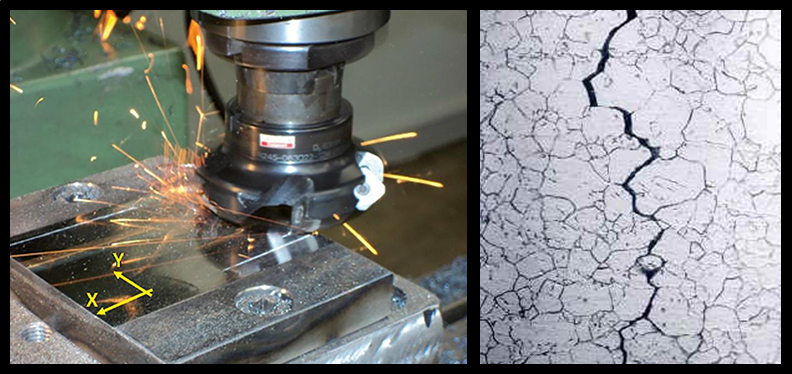

On welding projects, the condition of the base metals can make it such that you can’t join the materials. Conditions such as Stress Corrosion Cracking can create base metal and previous heat affected zones that make it difficult or even impossible to perform certain kinds of repair work.

Machining projects can also be made more complex because of material science. Due to heat cycles, prior weld repairs and unknown or incorrectly-specified materials, machining can take far longer than through hardened or toughened materials. This can drastically increase the time required to machine and – in some cases – the material cannot be machined at all – especially with portable equipment.

A reputable repair company will do everything they can to get your plant operational again. Just be sure to set your expectations appropriately and include contingencies in the event the material gremlins rear their ugly heads.