This is likely the toughest expectation of all to “manage” when it comes to work in the field. From sleep deprivation to problems at home; from disagreements with co-workers to…

The ISM Manufacturing Index (PMI) continued to decline in October, registering a 50.2 reading from the 50.9 level in September. The new orders metric contracted for the fifth consecutive month, possibly…

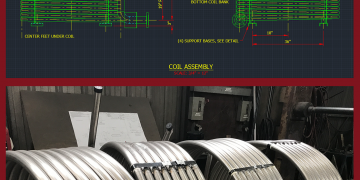

Field-Erected Tanks – Often times when a customer has a need for an API 650 storage tank, the size or location is such that there is no practical way to…

New Cooking Oil Heater – Ward was called on to help a new customer on an emergency basis. They had a fire in their tortilla chip manufacturing plant and their…

Vessel Head Repair Ward was called on to repair a section of the bottom head on a stainless steel half pipe reactor. This required that we remove sections of the…

The ASME Code is not a law. What makes it required? It is up to each jurisdiction to pass laws that require boilers or pressure vessels operating in that jurisdiction…